What is aluminum coil 6082? 6082 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6082 aluminum coil is an aluminum primarily alloyed with silicon and manganese. The addition of manganese controls the grain structure which in turn results in a stronger alloy. The most common tempers for 6082 aluminum are O, T4, T6 and T651 and 6082 is slightly higher mechanical properties in the T6 condition when ...

4000 Series Aluminum Coil Overview: What is 4000 series aluminum coil? 4000 series alloy aluminum coil represents 4A01, 4000 series aluminum coil belongs to the series with the high silicon content. Usually, the silicon content is between 4.5 and 6.0%. It is material for construction, machinery parts, forging, and welding; 4000 series aluminum alloy aluminum coils are aluminum alloys with silicon as the ...

7075 aluminum coil introduction Alloy 7075 aluminum coil have been and remain the baseline standard with a good balance of properties required for aerospace applications. 7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Corrosion resistance and machinability are rated as fair, though the addition of chromium provides good stress-corrosion cracking resistance in 70 ...

What is 5052 alloy aluminum coil? 5052 alloy aluminum coil belongs to 5xxx series aluminum coil. 5052 aluminum coil have good workability, high fatigue strength and good weldability. It has very good corrosion resistance, especially in marine environments. 5052 aluminum coil can be anodized to improve the corrosion resistance of the material in corrosive environments.5052 aluminum coil is stronger than 1100 and ...

Aluminum coil custom description: This alloy is an aluminum-based alloy in the "commercially pure" wrought family. With a minimum of 99.0% aluminum. It is the mechanically strongest alloy in the series, and is the only 1000-series alloy commonly used in rivets. At the same time, it keeps the benefits of being relatively lightly alloyed (compared to other series), such as high electrical conductivity, corrosion ...

What is 1060 aluminum coil? 1060 aluminium coil is pretty similar to 1050 aluminium alloy with more than 0.1% of aluminium by weight. Both 1050 and 1060 aluminium coil of Huawei AL, lives up to ISO standards, but they cover different ASTM standards. 1060 aluminium coil contains 0.05% cooper, thus, its conductivity is 55%. Besides, the 1060 aluminium coil is relatively low strength, essentially pure aluminium all ...

Alloy 5251 belongs to the Al-Mg system with low magnesium and cannot be strengthened by heat treatment. It has good corrosion resistance, weldability, medium strength and good plasticity, and is easy to be processed and formed. In foreign countries, 5251 aluminum alloy sheets with different heat treatment states are the main materials used in automobile manufacturing, canning industry and other fields; in Chin ...

In the process of making aluminum coil, in order to help change its shape, we need to heat it at high temperature. It will be softer at high temperature, and its shape is easier to undergo some changes. Adjust the shape. After that, the temperature can be lowered to maintain a certain hardness. However, in some cases, after the high-temperature cooling is completed, the aluminum coil will have some curling proble ...

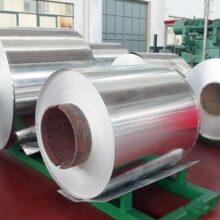

Aluminum coil product introduction Aluminum coil is a product made of aluminum plate or strip rolled into a roll. Aluminum coils are usually made of aluminum and its alloys and are widely used in construction, transportation, electronics, packaging, and various other industries. The use of aluminum coils has many advantages, including lightweight, corrosion resistance, easy processing, and good thermal conductiv ...

The 4000 series aluminum coil is an Al+Si alloy (silicon content between 4.5-6.0%), which is an aluminum alloy with a high silicon content. This aluminum alloy with silicon as the main alloying element cannot be strengthened by heat treatment. Mostly used for construction and some mechanical parts. 4 series aluminum coils have the characteristics of low melting point, high temperature resistance and wear r ...

The aluminum coil is different from the aluminum plate. The aluminum coil is cylindrical, while the aluminum plate is square. Knowing that the length, width and thickness can be calculated in the form of weight = density * volume. The calculation of the aluminum coil needs to know the coil diameter, width, and outer diameter of the coil core. By calculating the overall weight and subtracting the blank part of ...

The exquisite surface and excellent quality of thermal insulation aluminum coils have become the first choice of users in many fields. Because of the different uses, they need to pay special attention when applying them. So, what are the precautions for the application of thermal insulation aluminum coil? Let me explain to you: First, if it is to be put into use, it must be at a normal temperature, and the tem ...