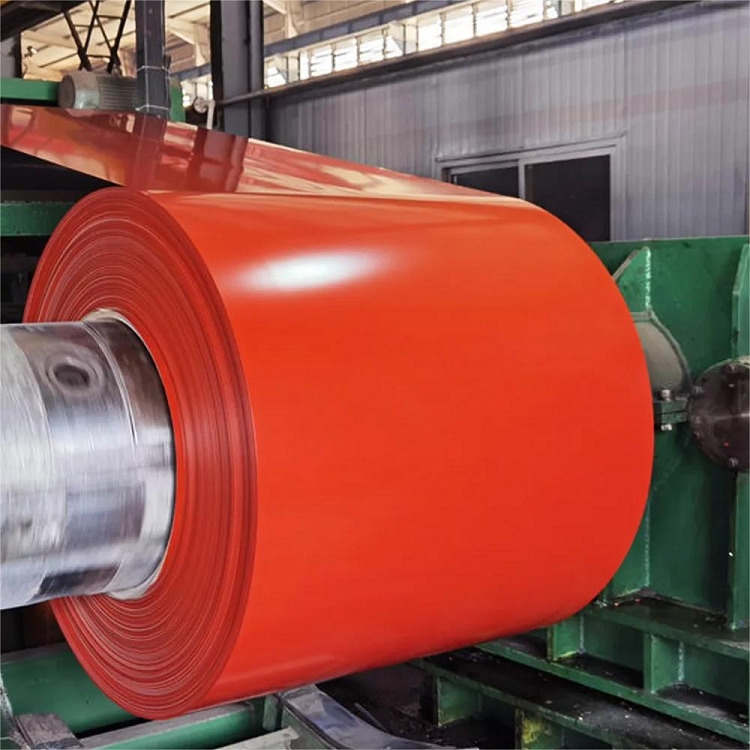

Aluminum coil for cladding panel overview What is ACP(Aluminum composite panels)? Aluminum composite panels (ACP) are built by inserting a soft, shock-absorbent core (typically plastic) sandwiched between two layers of aluminum sheet metal. And one of its main uses is aluminum composite panel cladding for buildings. Aluminum cladding panels coil also called a painted aluminum coil. Aluminum composite pan ...

What is aluminum 5083 alloy coil? 5083 aluminium coil belongs to Al-Mg-Si aluminium alloys. Its main contents are Magnesium and Silicon except Aluminium. Over 4.0% of Magnesium enables 5083 aluminium coil to have excellent resistance to correction, and easily to welded. By adding cooper, 5083 aluminium coil has 28% Electrical conductivity. 5083 aluminium coil also has good forming characteristic for either hot o ...

3105 aluminum coil introduction What is 3105 aluminum coil?3105 aluminum coil with 98% pure aluminum and slight alloy additions for strength. 0.3% of copper is added to 3105 aluminum coil, so the conductivity turns out to be 41%. For its contents and processing technologies, 3105 aluminumcoil is light in weight and it has semi-smooth surface. Besides, it is not hardened by heat treatment. All the products Of Hua ...

What is aluminum gutter coil? First we need to know what is a gutter? The gutter refers to the concave part between the two spans of the building roof, which is used to collect rainwater, and the gutter aluminum coil can effectively dredge the roof drainage in an organized manner and play a role in protecting the building. The gutter is divided into inner gutter and outer gutter, and inner gutter refers to the g ...

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum convallis, magna tempus tempor gravida, ante nibh accumsan leo, ut facilisis metus felis ac nunc. Proin purus dui, porta eu metus at, malesuada mollis augue. Sed eu vehicula lectus. Integer placerat, est id cursus ullamcorper, ex nulla lobortis neque, sed bibendum tellus metus eu nunc. Suspendisse potenti. In suscipit, tortor id interdum convalli ...

What is 5052 alloy aluminum coil? 5052 alloy aluminum coil belongs to 5xxx series aluminum coil. 5052 aluminum coil have good workability, high fatigue strength and good weldability. It has very good corrosion resistance, especially in marine environments. 5052 aluminum coil can be anodized to improve the corrosion resistance of the material in corrosive environments.5052 aluminum coil is stronger than 1100 and ...

Aluminum coils have many processing states in the production process, and different production requirements correspond to different states. Many people may not know about these states. Today, HWALU is here to share with you the various states of aluminum coils. Aluminum coil temper quick details--1 H1 pure work hardening state; suitable for the state where the required strength is obtained only by work ...

Overview: Aluminum alloy has a wide range of applications in the world. For uniformity of production and processing, a number of conventional alloy sizes have been developed in different countries. The following are the usual specifications and sizes of aluminum products arranged by HWALU for you 1. The Aluminum Sheet The aluminum sheet material whose thickness is more than 0.2mm to less than 500mm, width i ...

1000-8000 series alloy Al 1000 series (Pure) 1050,1060,1070,1100,1145,1199,1200,1230,1350,1370,1420,1421 1424,1430,1440,1441,1445,1450,1460,1461,1464,1469 Al-Cu 2000 series 2004,2011,2014,2017,2020,2024,2025,2029,2036,2048,2055, 20802090,2091,2094,2095,2097,2098,2099,2124,2195,2196 2197,2198,2218,2219,2224&2324,2297,2319,2397,2519 Al-Mn 3000 series 3003,3 ...

7075 aluminum coil and sheet have been and remain the baseline standard with a good balance of properties required for aerospace applications. 7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Corrosion resistance and machinability are rated as fair, though the addition of chromium provides good stress-corrosion cracking resistance in 7075 aluminum sheet products. As ...

5251 alloy aluminum coil is a commonly used high-strength aluminum alloy material with excellent corrosion resistance and weldability, suitable for various applications. The following are the top ten applications of 5251 alloy aluminum coil: Shipbuilding: 5251 alloy aluminum coils are suitable for the manufacture of ship hulls and decks and other components because of their corrosion resistance and resistance ...

The size below 159 is generally 0.45mm, and the elbow can also be pressed out. If it is large, it is generally 0.5mm. Of course, there are also 0.7mm ones, or the elbow is too soft. So, everyone should understand. Of course, the insiders watch the doorways, and the laymen watch the excitement. Before doing this, I asked me these questions. I don't even know what the thickness is 0.45mm. It was only after years of ...