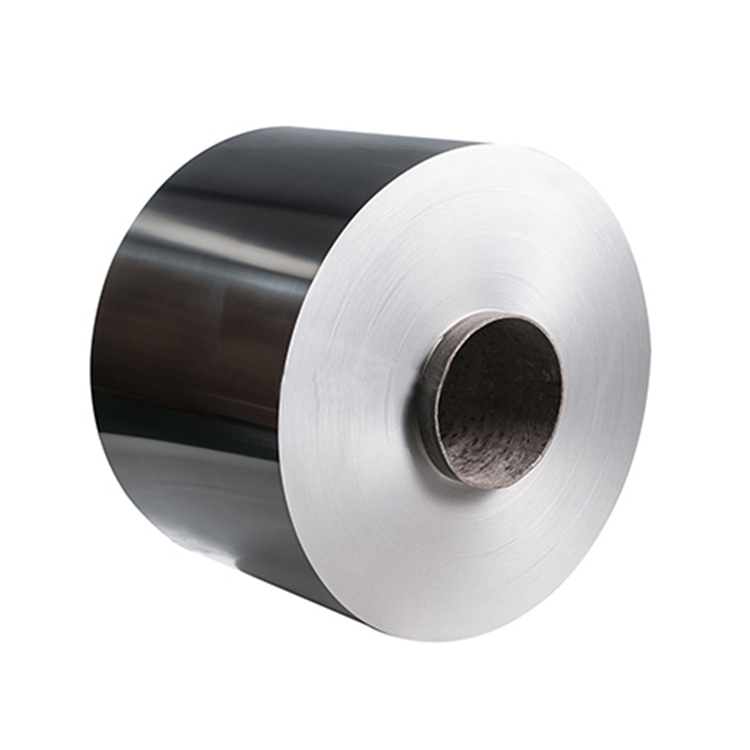

What is 6063 aluminum alloy coil? 6063 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6063 aluminum coil is an aluminum alloy with magnesium and silicon as the alloying elements. HuaWei Al delivers customized 6063 aluminum coil, plate and coil with excellent properties like weldability, corrosion resistance and machinability. The mechanical properties of 6063 depend greatly on the temper, or he ...

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum convallis, magna tempus tempor gravida, ante nibh accumsan leo, ut facilisis metus felis ac nunc. Proin purus dui, porta eu metus at, malesuada mollis augue. Sed eu vehicula lectus. Integer placerat, est id cursus ullamcorper, ex nulla lobortis neque, sed bibendum tellus metus eu nunc. Suspendisse potenti. In suscipit, tortor id interdum convalli ...

What are the alloy models of aluminum coil stock? Aluminum coils are available in a variety of alloy types, which are designated by a four-digit number according to the Aluminum Institute's Alloy Nomenclature System. Some common aluminum coil alloy models are: 1000 series 1100 coil stock: A commercially pure aluminum alloy with excellent corrosion resistance and good formability. It is commonly used in applic ...

7000 Series Aluminum Coil Overview: 7000 series aluminum coil represents 7075 mainly contains zinc elements. 7075 aluminum coils are stress relieved and will not be deformed or warped after processing. All super large and thick 7075 aluminum coils are ultrasonically inspected to ensure that there is no grit, impurities. 7075 aluminum coils have high thermal conductivity, which can shorten the molding time and ...

Learn more 3003 h14 aluminum coil 3003 H14 aluminum coil is one of the most common tempers in 3 series aluminum alloy products, and it is also used to make 3003 h14 aluminum circle. The aluminum plate is soft, but slightly harder than the fully soft aluminum plate. It is suitable for shallow stretch products and products that have certain requirements for strength. 3003 h14 aluminum coil has good corrosion resis ...

What is aluminum coil anodizing? Aluminum coil anodizing is a process that involves electrochemically treating the surface of an aluminum coil to create a durable and corrosion-resistant oxide layer. The process involves immersing the aluminum coil in an electrolytic solution and applying an electric current to the coil. This causes a controlled oxidation reaction to occur, which produces a thick layer of alumin ...

1. What is the product specification of 3000 Alloy? Alloy number: 3003, 3004, 3A21, 3105, etc Tempering: O, H12, H14, H24, H16, H26, H18, Thickness: 0.2mm-12mm Width: 20mm to 2600mm Maximum length: 11.8 m or coiled, Packing: Standard airworthiness export packing, fumigated wooden pallets, Delivery time: 30 days Terms of payment: T/T, sight l/C Surface treatment: key surface quality: no chatter, no Pitt m ...

It is understood that the current aluminum coils on the market are widely used in the production of aluminum composite panels, aluminum ceilings, fireproof veneers, garage doors and other products, but there are certain shortcomings, that is, they don’t pay attention to the protection of aluminum coils after a long time. , There will be corrosion, how to effectively prevent it, let's take a look? (1) Aluminum ...

China is the world's largest producer of electrolytic aluminum, and aluminum alloys are naturally widely used. Aluminum skin is a common aluminum alloy product and is currently widely used in pipeline anti-corrosion and heat preservation projects. At present, the amount of aluminum skin in my country has been increasing year by year, and it has become a relatively important part of the sale of aluminum strips. ...

The density of aluminum alloys may vary depending on the specific alloy composition and the heat treatment process it undergoes. The 4000 series aluminum alloy is a typical aluminum-silicon alloy. The characteristics of the 4000 series aluminum alloy include good corrosion resistance and good welding performance. Common 4000 series aluminum alloys mainly include 4043 4047 4145 aluminum coil 4043 alloy: Cont ...

Color-coated aluminum coil is an aluminum coil that has been color-coated. It has the advantages of good decoration, corrosion resistance, heat resistance, and strong weather resistance. It is widely used in construction, home appliances, transportation and other fields. The following are ten applications of color-coated aluminum coils: Building decoration materials: Color-coated aluminum coils can be used for ...

There are a few different methods that can be used to measure the weight of an aluminum coil, depending on the equipment and tools you have available. Here are three common methods: Using a scale: The most straightforward way to measure the weight of an aluminum coil is to use a scale. You will need a scale that can handle the weight of the coil. Place the coil on the scale and ...