What is 6061 Aluminium alloy coil? 6061 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6061 aluminum coils is the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum coil provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the "O" t ...

What is aluminum gutter coil? First we need to know what is a gutter? The gutter refers to the concave part between the two spans of the building roof, which is used to collect rainwater, and the gutter aluminum coil can effectively dredge the roof drainage in an organized manner and play a role in protecting the building. The gutter is divided into inner gutter and outer gutter, and inner gutter refers to the g ...

What is 6061 Aluminium alloy coil? 6061 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6061 aluminum coils is the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum coil provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the "O" t ...

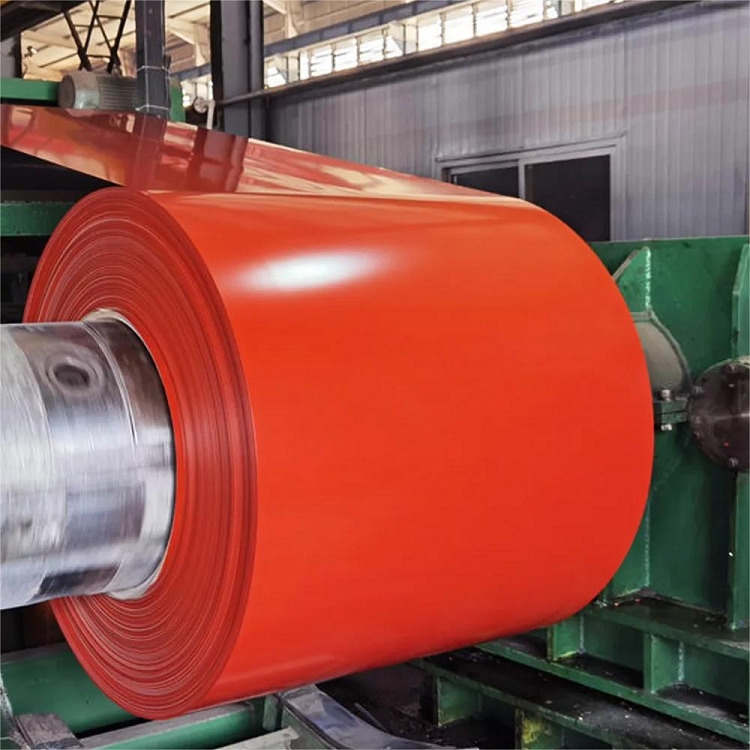

Aluminum coil for cladding panel overview What is ACP(Aluminum composite panels)? Aluminum composite panels (ACP) are built by inserting a soft, shock-absorbent core (typically plastic) sandwiched between two layers of aluminum sheet metal. And one of its main uses is aluminum composite panel cladding for buildings. Aluminum cladding panels coil also called a painted aluminum coil. Aluminum composite pan ...

What is aluminum coil anodizing? Aluminum coil anodizing is a process that involves electrochemically treating the surface of an aluminum coil to create a durable and corrosion-resistant oxide layer. The process involves immersing the aluminum coil in an electrolytic solution and applying an electric current to the coil. This causes a controlled oxidation reaction to occur, which produces a thick layer of alumin ...

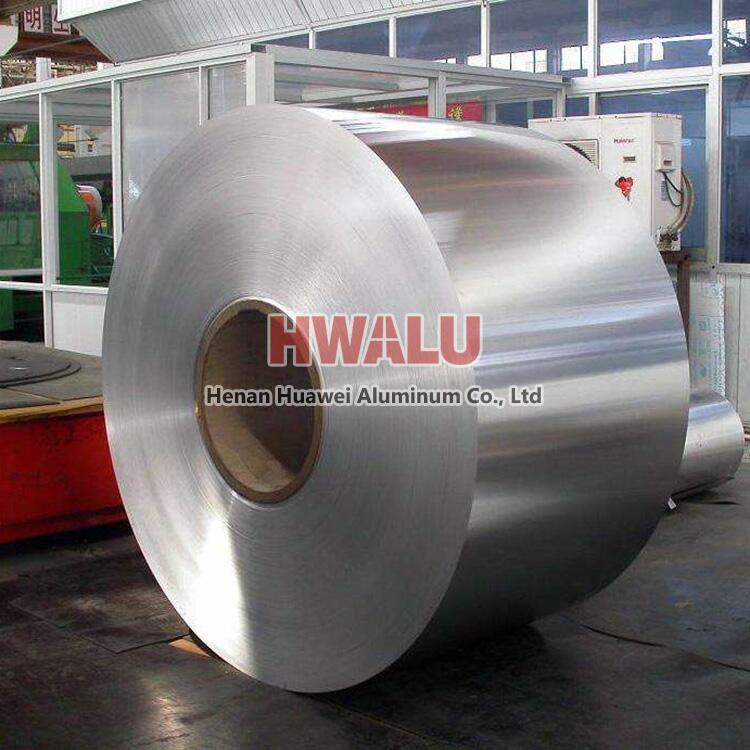

Aluminum coil product Aluminum coil is a rolled product rolled from pure aluminum or aluminum alloy materials, with a silvery white and shiny surface. Aluminum coils are lightweight, corrosion-resistant, and have good thermal conductivity. After rolling and bending processing, they can be widely used in construction, transportation, electrical appliance manufacturing and other fields. Aluminum ac coil One of t ...

The density of aluminum alloys may vary depending on the specific alloy composition and the heat treatment process it undergoes. The 4000 series aluminum alloy is a typical aluminum-silicon alloy. The characteristics of the 4000 series aluminum alloy include good corrosion resistance and good welding performance. Common 4000 series aluminum alloys mainly include 4043 4047 4145 aluminum coil 4043 alloy: Cont ...

The production process of painted aluminum coils usually involves several steps in order to apply protective and decorative coatings to the aluminum coils. Painting aluminum coils enhances the appearance of aluminum and is more environmentally friendly. The process of painting aluminum coils generally includes several processes 1. Preparation of aluminum coils: Uncoiling: A coil of aluminum is uncoiled from a ...

5000 series aluminum coils belong to Al+Mg alloy aluminum coils, in which the content of magnesium metal reaches 3%-5%, which is an aluminum alloy with good hardness and strength. China's 5-series aluminum alloy products have complete and mature processing technology, and have been widely exported to all over the world in recent years. The representative alloy aluminum coils of the 5 series aluminum alloys ...

Both 3104 and 3004 are commonly used aluminum alloy coils in various applications, but there are some differences in their chemical composition and properties. The following is a comparison of 3104 aluminum coils and 3004 aluminum coils: chemical composition: 3104 aluminum coil: Aluminum (Al): 95.7% Magnesium (Mg): 0.8-1.3% Manganese (Mn): 0.8-1.3% Zinc (Zn): 0.25% Other elements: Trace other elements 300 ...

Aluminum coils have many processing states in the production process, and different production requirements correspond to different states. Many people may not know about these states. Today, HWALU is here to share with you the various states of aluminum coils. Aluminum coil temper quick details--1 H1 pure work hardening state; suitable for the state where the required strength is obtained only by work ...

The exquisite surface and excellent quality of thermal insulation aluminum coils have become the first choice of users in many fields. Because of the different uses, they need to pay special attention when applying them. So, what are the precautions for the application of thermal insulation aluminum coil? Let me explain to you: First, if it is to be put into use, it must be at a normal temperature, and the tem ...