What is 6063 aluminum alloy coil? 6063 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6063 aluminum coil is an aluminum alloy with magnesium and silicon as the alloying elements. HuaWei Al delivers customized 6063 aluminum coil, plate and coil with excellent properties like weldability, corrosion resistance and machinability. The mechanical properties of 6063 depend greatly on the temper, or he ...

1070 aluminum coil alloy introduction 1070 aluminium coil has some features such as high plasticity, anti-corrosion, electrical conductivity and good thermal conductivity, but low strength. And the machinability is not good without heat treatment. It can be used for gas welding. This specific properties of 1070 aluminium alloy can be used to produce some structures such as aluminium gasket and capacitor, electro ...

What is aluminum gutter coil? First we need to know what is a gutter? The gutter refers to the concave part between the two spans of the building roof, which is used to collect rainwater, and the gutter aluminum coil can effectively dredge the roof drainage in an organized manner and play a role in protecting the building. The gutter is divided into inner gutter and outer gutter, and inner gutter refers to the g ...

5086 aluminum coil description: 5086 aluminum coil has high strength capacity than 5052 and 5083 aluminum coil, but it is not strengthened by heat treatment, instead becoming stronger due to strain hardening or cold mechanical working of the material.3.0%-4.5% of magnesium is added to 5086 aluminum plate, which enable it to have high strength. Heat treatment does not strongly affect the strength, so 5086 aluminu ...

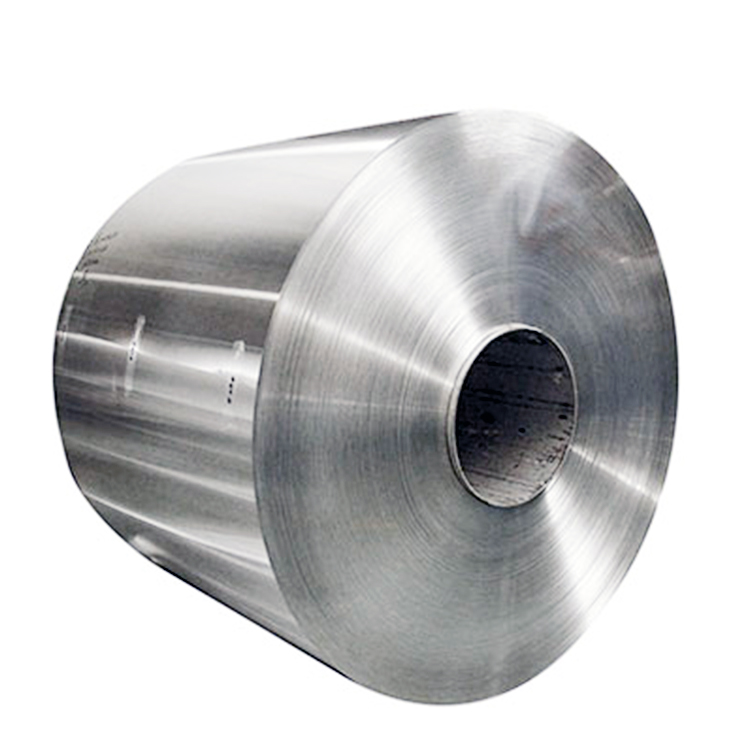

5000 Series Alloy Aluminum Coil Overview: What is 5 series aluminum coil? The main element is magnesium, the magnesium content is between 3-5%(Al-Mg Alloy). 5000 series alloy aluminum coil represents 5052, 5005, 5083, 5A05 series. 5000 series aluminum coil belongs to the more commonly used alloy aluminum sheet series. It can also be called an aluminum-magnesium alloy. The main characteristics are low densit ...

What is aluminum coil anodizing? Aluminum coil anodizing is a process that involves electrochemically treating the surface of an aluminum coil to create a durable and corrosion-resistant oxide layer. The process involves immersing the aluminum coil in an electrolytic solution and applying an electric current to the coil. This causes a controlled oxidation reaction to occur, which produces a thick layer of alumin ...

Aluminum coil packaging requirements The packaging of aluminum coils should be based on the specifications and dimensions of the product to choose the packaging box and packaging method. For box packaging, the product cannot be squeezed or moved after being packed in the box. The packaging box can be made of wood, multi-layer board, fiberboard, metal and other materials. The packaging box should be clean and tid ...

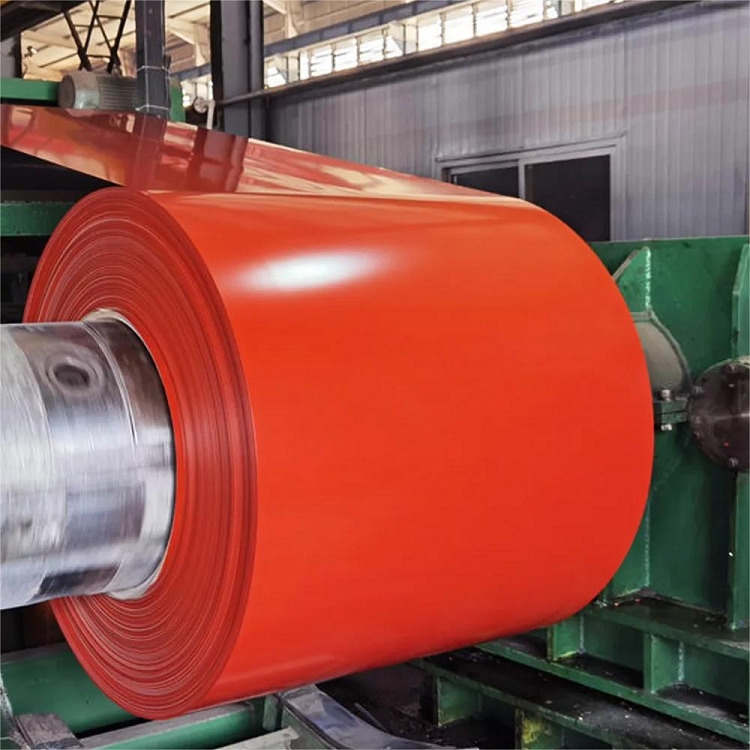

The purpose of the coating of aluminum coils is to make the coating on the surface of the aluminum coil through the coating construction to form a solid continuous coating and play its role in decoration, protection and special functions. After the aluminum coil is coated, the coating is covered on its surface, forming a solid continuous coating with corrosion -resistant effects to isolate the aluminum coil su ...

3004 aluminum coils are commonly used in various applications due to their excellent combination of formability, strength, and corrosion resistance. Here are some common uses of 3004 aluminum coils: Building and Construction: 3004 aluminum coils are often used in building and construction projects, particularly for roofing and siding. They are also used in the fabrication of gutters, downspouts, and other ex ...

We all know that aluminum is a solid metal, so can solid aluminum become liquid aluminum? The answer is yes. Aluminum can be melted into liquid aluminum when heated to the right temperature. Aluminum has a melting point of about 660 degrees Celsius (1220 degrees Fahrenheit). When aluminum reaches or exceeds this temperature, it changes from solid to liquid. At high temperatures, aluminum's lattice structure be ...

Aluminum gutter coil is a popular material used in the construction industry for the fabrication of gutters and downspouts. It offers several advantages over other materials, such as durability, lightweight, corrosion resistance, and ease of installation. Here are some common usage scenarios for aluminum gutter coil: Residential and Commercial Buildings: Aluminum gutter coil is ...

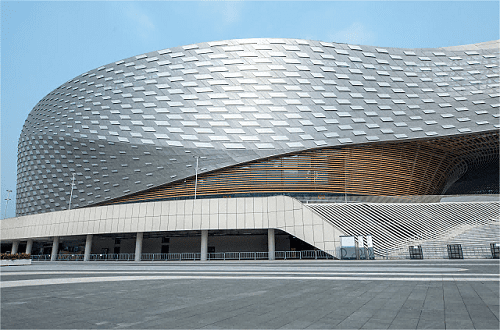

Aluminum coils have many uses in the construction field and can be used as building materials. In terms of building structures, aluminum coils can be used to make frames and panels for roofs, exterior walls, doors, windows, balconies, etc. The lightness and high strength of aluminum coils allow it to replace traditional materials such as reinforced concrete and wood, reduce the weight of buildings, and improve th ...