What is 3003 aluminum coil? 3003 belongs to one of the 3 series aluminum alloys,which is Al Mn alloy, which is the most widely used antirust aluminum. The strength of this alloy is not high (slightly higher than that of industrial pure aluminum) and cannot be strengthened by heat treatment. Therefore, cold working method is adopted improve its mechanical properties. It is used to process parts and components tha ...

Aluminum coil custom description: This alloy is an aluminum-based alloy in the "commercially pure" wrought family. With a minimum of 99.0% aluminum. It is the mechanically strongest alloy in the series, and is the only 1000-series alloy commonly used in rivets. At the same time, it keeps the benefits of being relatively lightly alloyed (compared to other series), such as high electrical conductivity, corrosion ...

What is 6063 aluminum alloy coil? 6063 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6063 aluminum coil is an aluminum alloy with magnesium and silicon as the alloying elements. HuaWei Al delivers customized 6063 aluminum coil, plate and coil with excellent properties like weldability, corrosion resistance and machinability. The mechanical properties of 6063 depend greatly on the temper, or he ...

Aluminum coil size customization instructions Alloy Thickness(mm) Width(mm) Temper DC or CC 1050,1060,1070,1100,1235,1145 0.2-4.0 20-1500 O,H12,H22,H14,H24,H16,H26,H18 DC, CC 4.0-12.0 1000-1900 H111,H112 DC 3003,3004,3105 0.2-4.0 20-1500 O,H12,H22,H14,H24,H16,H26,H18 DC, CC 4.0-12.0 1000-1900 H111,H112 DC 5052,5083,5754,5005 0.2-4.0 20-1500 O,H12,H22,H14,H24, ...

What is aluminum coil grade 5005 ? 5005 alloy aluminum coil belongs to 5000 series alloy aluminum coil. 5005 aluminum coil of HuaWei Alu is certificated to ASTM, EN as well as JIS, etc. and it can be cut to size at customers’ need. Mg is the principal element in the 5005 aluminum coil and when it used as main alloying element or combined with Mn, high strength and no-heat treatable properties can be realized. 50 ...

What is 5182 aluminum coil? 5182 aluminum coil is an Al-Mg alloy, which is one of the representative models of 5 series aluminum alloy coils. 5182 aluminum alloy has medium metal strength, good welding performance, and can be anodized on the surface. Its excellent corrosion resistance and plasticity make 5182 aluminum coil widely used in automobile manufacturing and ship transportation. 5182 alloy aluminum ...

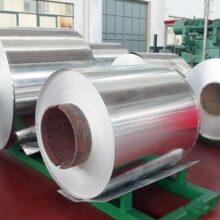

Aluminum coil is a kind of metal sheet, which is melted from aluminum ingots, plus different alloys, and processed into aluminum coils by casting or hot rolling, cold rolling, annealing, cross-cutting and other processes. It is widely used in industry and life. There are more applications. Today we will talk about the ten characteristics of aluminum foil. What are the characteristics of aluminum coil: 1. Low d ...

3003 aluminum coils and 1060 aluminum coils are commonly used for thermal insulation aluminum coils. Which of these two has more advantages? 1060 aluminum coil vs 3003 aluminum coil. 1060 aluminum coil with an aluminum content of more than 99.6% is also called pure aluminum strip, which belongs to a commonly used series in the aluminum strip family. 3003 aluminum coil is also called anti-rust aluminum skin becau ...

1050 aluminum coil is a product in the pure aluminum series. 1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, acceptable for contact welding ,gas welding. The production process is relatively simple and the price is relatively cheap. It is a series co ...

The exquisite surface and excellent quality of thermal insulation aluminum coils have become the first choice of users in many fields. Because of the different uses, they need to pay special attention when applying them. So, what are the precautions for the application of thermal insulation aluminum coil? Let me explain to you: First, if it is to be put into use, it must be at a normal temperature, and the tem ...

The aluminum coil is different from the aluminum plate. The aluminum coil is cylindrical, while the aluminum plate is square. Knowing that the length, width and thickness can be calculated in the form of weight = density * volume. The calculation of the aluminum coil needs to know the coil diameter, width, and outer diameter of the coil core. By calculating the overall weight and subtracting the blank part of ...

In the process of making aluminum coil, in order to help change its shape, we need to heat it at high temperature. It will be softer at high temperature, and its shape is easier to undergo some changes. Adjust the shape. After that, the temperature can be lowered to maintain a certain hardness. However, in some cases, after the high-temperature cooling is completed, the aluminum coil will have some curling proble ...