What is aluminum coil 6082? 6082 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6082 aluminum coil is an aluminum primarily alloyed with silicon and manganese. The addition of manganese controls the grain structure which in turn results in a stronger alloy. The most common tempers for 6082 aluminum are O, T4, T6 and T651 and 6082 is slightly higher mechanical properties in the T6 condition when ...

5251 alloy aluminum coil overview 5251 aluminum coil is a relatively strong aluminum coil series in the 5 series aluminum alloy products. Aluminium alloy 5251 contains nominally 2.0% magnesium & 0.30% manganese. It has good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres. It also has the low density and excel ...

7000 Series Aluminum Coil Overview: 7000 series aluminum coil represents 7075 mainly contains zinc elements. 7075 aluminum coils are stress relieved and will not be deformed or warped after processing. All super large and thick 7075 aluminum coils are ultrasonically inspected to ensure that there is no grit, impurities. 7075 aluminum coils have high thermal conductivity, which can shorten the molding time and ...

3004 aluminum coil alloy introduction 3004 aluminium coil is a non- heat treatable aluminium alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 aluminum vs 3003 aluminum coil 3004 aluminium coil belongs to AL-Mn alloy series, which has higher s ...

Why use 3104 aluminum coil for cans? Aluminum coil is widely used for cans because it is lightweight, durable, and can be easily shaped into various sizes and designs. Here are some of the key reasons why aluminum is a popular material for cans: Lightweight: 3104 aluminum coil is a lightweight material, which means that cans made from it are easy to transport and handle. This is particularly important for the ...

5754 aluminum coil introduction 5754 aluminum coil is a typical alloy of Al-Mg elements with moderate strength, excellent processing performance, good corrosion resistance, weldability and easy forming characteristics. 5754 aluminum coil of different heat treatments are the main materials of manufacturing automotive industry (such as car door, mold, seal components), and the canning industry. 5754 aluminium ...

Product name: aluminum coil 1050 cold rolled SIZE (MM) ALLOY / TEMPER 0.8x340 1050 H14 1.3x150 1050 H14

Aluminum is very common in our lives, and we can see it in both industry and agriculture. 3003 alloy aluminum coil is an AL-Mn alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum), so the chemical properties of 3003 alloy aluminum coil are excellent. In terms of corrosion resistance, 3003 alloy aluminum coil is very good ...

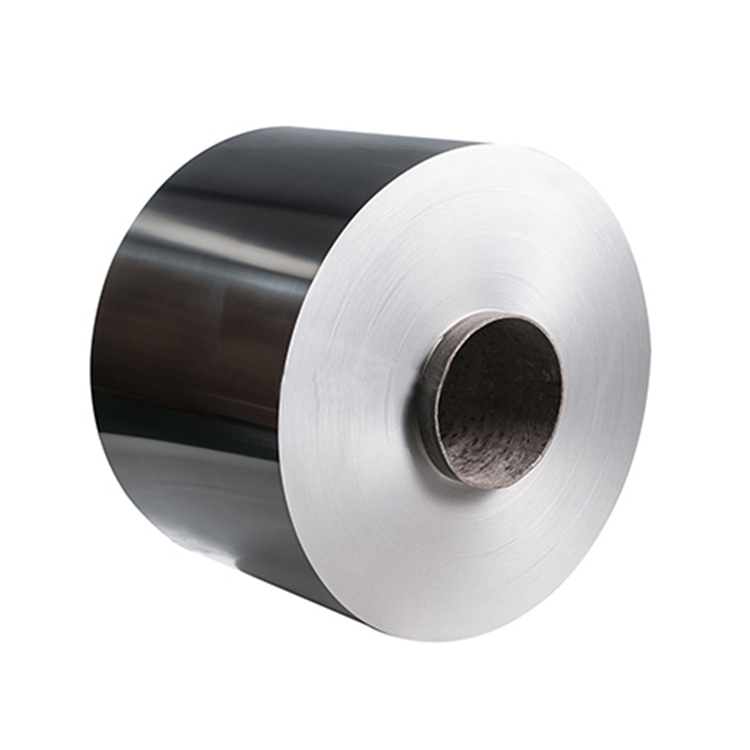

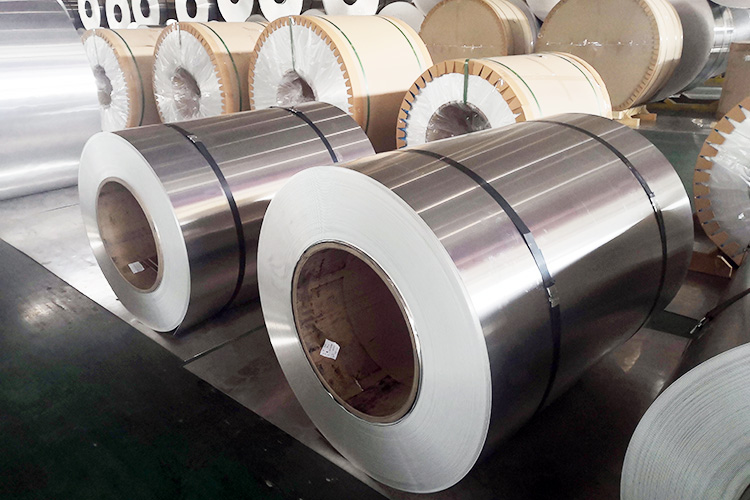

Aluminum coil is a kind of metal sheet, which is melted from aluminum ingots, plus different alloys, and processed into aluminum coils by casting or hot rolling, cold rolling, annealing, cross-cutting and other processes. It is widely used in industry and life. There are more applications. Today we will talk about the ten characteristics of aluminum foil. What are the characteristics of aluminum coil: 1. Low d ...

We all know that aluminum is a solid metal, so can solid aluminum become liquid aluminum? The answer is yes. Aluminum can be melted into liquid aluminum when heated to the right temperature. Aluminum has a melting point of about 660 degrees Celsius (1220 degrees Fahrenheit). When aluminum reaches or exceeds this temperature, it changes from solid to liquid. At high temperatures, aluminum's lattice structure be ...

3004 H14 and 3004 H34 are both aluminum alloys, but they differ in terms of their mechanical properties and temper designation. The "H" in the alloy designation stands for "strain-hardened," which means that the aluminum has been strengthened by a process of cold working or strain hardening. The number after the "H" indicates the level of strain hardening, with higher numbers indicating a greater degree of har ...

Aluminum gutter coil is a type of material used for creating seamless gutters. It is typically made from high-quality, durable aluminum alloy, which is known for its resistance to rust and corrosion. Some of the common uses of aluminum gutter coil include: Creating seamless gutters: Aluminum gutter coil is used to create seamless gutters, which offer a more attractive and functional option for managing rainwat ...