3000 Series Alloy Aluminum Coil Overview: 3000 series alloy aluminum coil represents 3003, 3105 mainly. It can also be called a rust-proof aluminum coil. 3000 series aluminum coil is made of manganese elements as the main component. The content is between 1.0 and 1.5. It is a series with a better rust-proof function. Routinely used in air conditioners, refrigerators, underneath cars, and other wet environments, ...

Aluminum coil custom description: This alloy is an aluminum-based alloy in the "commercially pure" wrought family. With a minimum of 99.0% aluminum. It is the mechanically strongest alloy in the series, and is the only 1000-series alloy commonly used in rivets. At the same time, it keeps the benefits of being relatively lightly alloyed (compared to other series), such as high electrical conductivity, corrosion ...

7075 aluminum coil introduction Alloy 7075 aluminum coil have been and remain the baseline standard with a good balance of properties required for aerospace applications. 7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Corrosion resistance and machinability are rated as fair, though the addition of chromium provides good stress-corrosion cracking resistance in 70 ...

3105 aluminum coil introduction What is 3105 aluminum coil?3105 aluminum coil with 98% pure aluminum and slight alloy additions for strength. 0.3% of copper is added to 3105 aluminum coil, so the conductivity turns out to be 41%. For its contents and processing technologies, 3105 aluminumcoil is light in weight and it has semi-smooth surface. Besides, it is not hardened by heat treatment. All the products Of Hua ...

1085 grade aluminum coil What is 1085 aluminum coil? 1085 aluminum alloy coil is a 1000 series aluminum alloy, and 1085 and 1050 1060 1075 1100 aluminum alloy are a kind of pure aluminum alloy coil. For primary forming into forged products. 1085 is also designated as EN AW-1085, Al99,85. 1085 aluminum alloy chemical elements(%) Alloy Fe Si Cu Mn Mg Zn Cr V Al 1085 ≤0.10 ≤0.12 ≤0.03 ...

What is 1200 aluminum alloy coil? 1200 aluminum alloy belongs to the 1000 series aluminum alloy series, which is a common industrial pure aluminum in the first series. The purity of 1200 aluminum coil aluminum is 99%, and the alloy has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. However, the strength of the pure aluminum series is low, the heat treatment cannot be s ...

1000 Series Aluminum Coil Sheet Description 1000 series aluminum alloy coil, which stands for 1050 1060 1070 1000 series aluminum coil, is also known as the pure aluminum coil, among all series 1000 series belongs to a series with the most aluminum content. The purity can reach more than 99.00%. Since it does not contain other technical elements, the production process is relatively single and the price is relat ...

The 1200 pure aluminum coil finds applications in various industries due to its specific properties. Some common applications of 1200 pure aluminum coil include: Electrical industry: 1200 pure aluminum coil is used in the electrical industry for manufacturing electrical conductors, transformer windings, and wiring due to its excellent electrical conductivity. Heat exchang ...

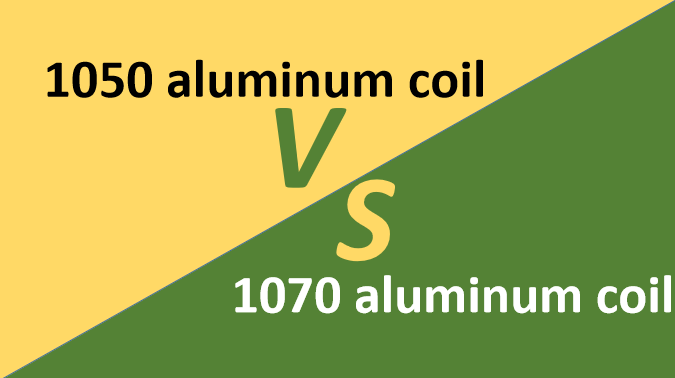

1050 and 1070 are both pure aluminum alloys with very similar chemical compositions, but there are some differences between them that make them suitable for different applications. 1050 aluminum coil contains 99.5% aluminum, while 1070 aluminum coil contains 99.7% aluminum. This small difference in aluminum content can result in slightly different properties and characteristics. 1050 aluminum coil is often ...

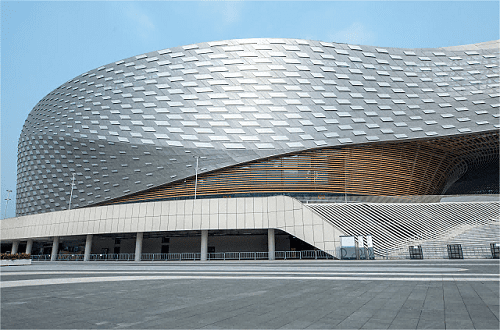

Color-coated aluminum coil is an aluminum coil that has been color-coated. It has the advantages of good decoration, corrosion resistance, heat resistance, and strong weather resistance. It is widely used in construction, home appliances, transportation and other fields. The following are ten applications of color-coated aluminum coils: Building decoration materials: Color-coated aluminum coils can be used for ...

Huawei Aluminum sorts out the five characteristics of color-coated aluminum 1. Flatness: no composite high-temperature indentation on the surface, no residual stress on the board surface, and no deformation after shearing; 2. Decoration: painted wood grain, stone grain, with realistic and real texture; 3. Weather resistance: The baked varnish pattern formed by continuous coating and high-temperature baking has ...

Aluminum coils have many uses in the construction field and can be used as building materials. In terms of building structures, aluminum coils can be used to make frames and panels for roofs, exterior walls, doors, windows, balconies, etc. The lightness and high strength of aluminum coils allow it to replace traditional materials such as reinforced concrete and wood, reduce the weight of buildings, and improve th ...