6000 Series Aluminum Alloy Coil Overview What is 6xxx series aluminum coil? 6000 series aluminum alloy coil represents 6061, which contains mainly magnesium and silicon elements, so it concentrates on the advantages of 4000 series and 5000 series. 6061 aluminum coil is a cold-treated aluminum forging product, suitable for applications requiring high corrosion resistance and oxidation. It has good service ...

What are the alloy models of aluminum coil stock? Aluminum coils are available in a variety of alloy types, which are designated by a four-digit number according to the Aluminum Institute's Alloy Nomenclature System. Some common aluminum coil alloy models are: 1000 series 1100 coil stock: A commercially pure aluminum alloy with excellent corrosion resistance and good formability. It is commonly used in applic ...

3004 aluminum coil alloy introduction 3004 aluminium coil is a non- heat treatable aluminium alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 aluminum vs 3003 aluminum coil 3004 aluminium coil belongs to AL-Mn alloy series, which has higher s ...

4000 Series Aluminum Coil Overview: What is 4000 series aluminum coil? 4000 series alloy aluminum coil represents 4A01, 4000 series aluminum coil belongs to the series with the high silicon content. Usually, the silicon content is between 4.5 and 6.0%. It is material for construction, machinery parts, forging, and welding; 4000 series aluminum alloy aluminum coils are aluminum alloys with silicon as the ...

What is 1100 series aluminum coil? 1100 aluminum coil is the most commercially pure alloy of all the aluminum grades. 1100 aluminum coil is available for various applications including chemical storage and processing equipemtn. Benefits of 1100 aluminum coil include a 99% or greater content of aluminum compared to other grades of aluminum. 1100 is a low strength aluminum alloy with excellent corrosion resistanc ...

During the production of aluminum coils, due to the high temperature of the liquid metal in the front box, the temperature distribution of the aluminum coils is uneven when flowing into the casting and rolling area, and the liquid cavities are deep at the local temperature too high. In the rolling zone, when the surface of the cast-rolled sheet is low in the liquid level of the tropical front box, the static pres ...

Coated aluminum coil is a type of aluminum coil that has been coated with a layer of protective material to enhance its durability, resistance to corrosion, and aesthetics. The characteristics of coated aluminum coil include: Durability: Coated aluminum coil has high durability and can withstand extreme weather conditions, making it ideal for outdoor use. Corrosion resistance: ...

1050 aluminum coil is a product in the pure aluminum series. 1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, acceptable for contact welding ,gas welding. The production process is relatively simple and the price is relatively cheap. It is a series co ...

With the advent of the 5G communication era, the integration of electronic communication equipment and products is gradually improving, and the calorific value per unit volume is also increasing. At this time, relevant materials and structures are required to have good thermal conductivity to ensure normal equipment and products. work and prolong life. Taking the 5G communication filter as an example, it has h ...

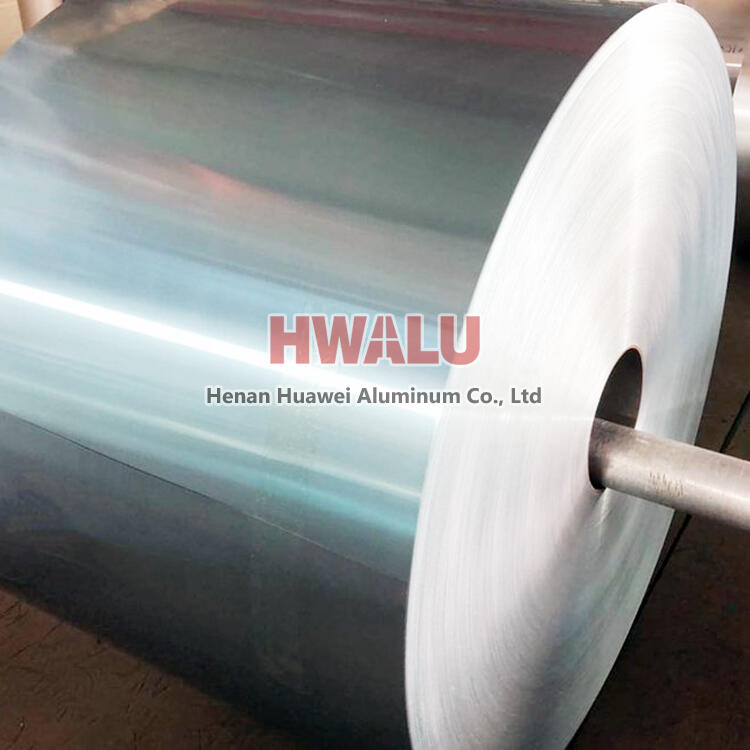

The process of making aluminum coils typically involves several steps. Here is a general overview of the process: Casting: The first step is to melt aluminum ingots or recycled aluminum to form a molten aluminum alloy. The molten aluminum is then cast into large rectangular-shaped molds called ingots. Hot Rolling: The aluminum ingots are heated and passed through a series of rolling mills. The ingots are gr ...

Aluminum gutter coil is a versatile material that is commonly used for gutter system installations and various other applications related to rainwater management. Here are some key areas where aluminum gutter coil can be used: Gutter Systems: The primary application of aluminum gutter coil is for manufacturing seamless gutters. It is used to fabricate the gutters, downspouts, an ...