3004 aluminum coil alloy introduction 3004 aluminium coil is a non- heat treatable aluminium alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 aluminum vs 3003 aluminum coil 3004 aluminium coil belongs to AL-Mn alloy series, which has higher s ...

Why use 3104 aluminum coil for cans? Aluminum coil is widely used for cans because it is lightweight, durable, and can be easily shaped into various sizes and designs. Here are some of the key reasons why aluminum is a popular material for cans: Lightweight: 3104 aluminum coil is a lightweight material, which means that cans made from it are easy to transport and handle. This is particularly important for the ...

6000 Series Aluminum Alloy Coil Overview What is 6xxx series aluminum coil? 6000 series aluminum alloy coil represents 6061, which contains mainly magnesium and silicon elements, so it concentrates on the advantages of 4000 series and 5000 series. 6061 aluminum coil is a cold-treated aluminum forging product, suitable for applications requiring high corrosion resistance and oxidation. It has good service ...

7075 aluminum coil introduction Alloy 7075 aluminum coil have been and remain the baseline standard with a good balance of properties required for aerospace applications. 7075 aluminum is among the highest strength alloys available and used in highly stressed parts. Corrosion resistance and machinability are rated as fair, though the addition of chromium provides good stress-corrosion cracking resistance in 70 ...

What is aluminum coil 6082? 6082 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6082 aluminum coil is an aluminum primarily alloyed with silicon and manganese. The addition of manganese controls the grain structure which in turn results in a stronger alloy. The most common tempers for 6082 aluminum are O, T4, T6 and T651 and 6082 is slightly higher mechanical properties in the T6 condition when ...

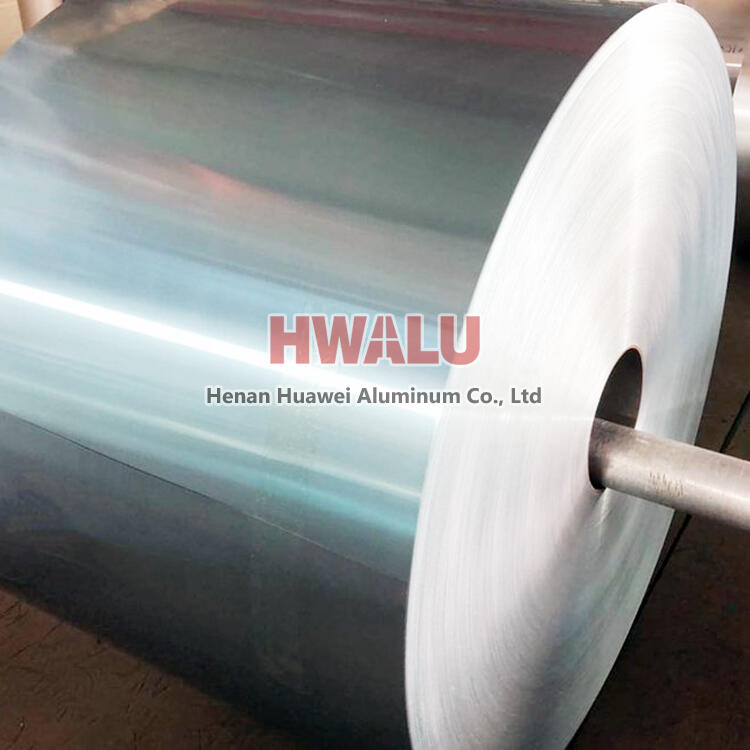

Aluminum coil product Aluminum coil is a rolled product rolled from pure aluminum or aluminum alloy materials, with a silvery white and shiny surface. Aluminum coils are lightweight, corrosion-resistant, and have good thermal conductivity. After rolling and bending processing, they can be widely used in construction, transportation, electrical appliance manufacturing and other fields. Aluminum ac coil One of t ...

Color-coated aluminum coil is an aluminum coil that has been color-coated. It has the advantages of good decoration, corrosion resistance, heat resistance, and strong weather resistance. It is widely used in construction, home appliances, transportation and other fields. The following are ten applications of color-coated aluminum coils: Building decoration materials: Color-coated aluminum coils can be used for ...

The superiority of aluminum coils over copper coils depends on a variety of factors such as cost, efficiency, durability, and application. Both aluminum coils and copper coils have their own advantages and disadvantages. Which one is better depends on the use. There are significant differences between aluminum coil and copper coil in many aspects. Comparison between aluminum coils and copper coils Co ...

The density of aluminum alloys may vary depending on the specific alloy composition and the heat treatment process it undergoes. The 4000 series aluminum alloy is a typical aluminum-silicon alloy. The characteristics of the 4000 series aluminum alloy include good corrosion resistance and good welding performance. Common 4000 series aluminum alloys mainly include 4043 4047 4145 aluminum coil 4043 alloy: Cont ...

In the process of making aluminum coil, in order to help change its shape, we need to heat it at high temperature. It will be softer at high temperature, and its shape is easier to undergo some changes. Adjust the shape. After that, the temperature can be lowered to maintain a certain hardness. However, in some cases, after the high-temperature cooling is completed, the aluminum coil will have some curling proble ...

Aluminum gutter coil is a type of material used for creating seamless gutters. It is typically made from high-quality, durable aluminum alloy, which is known for its resistance to rust and corrosion. Some of the common uses of aluminum gutter coil include: Creating seamless gutters: Aluminum gutter coil is used to create seamless gutters, which offer a more attractive and functional option for managing rainwat ...

Aluminum coil stock is available in a range of gauge thicknesses, which are commonly measured in terms of "gauge" or "mil." The gauge system is used to indicate the thickness of metal sheets or coils, where a higher gauge number corresponds to a thinner sheet. The mil system is another measurement of thickness, where 1 mil is equal to 0.001 inches. The specific gauge thickness of aluminum coil stock can vary d ...