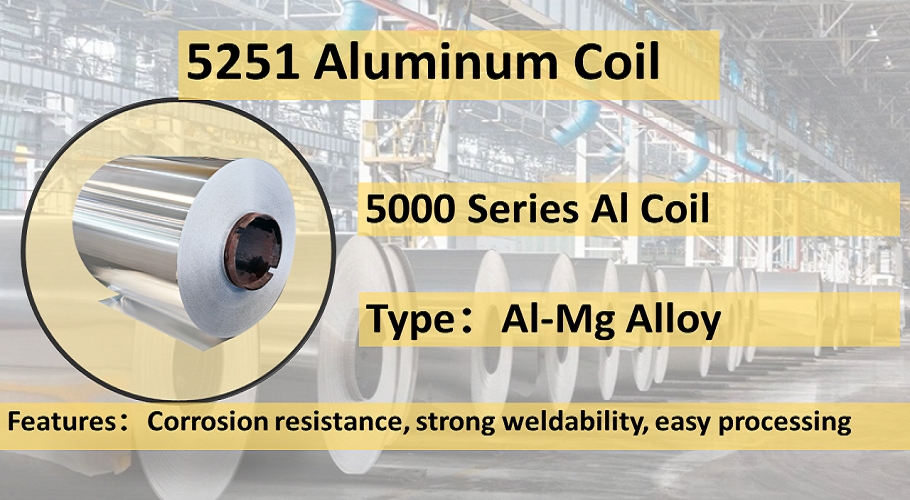

5251 alloy aluminum coil overview 5251 aluminum coil is a relatively strong aluminum coil series in the 5 series aluminum alloy products. Aluminium alloy 5251 contains nominally 2.0% magnesium & 0.30% manganese. It has good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres. It also has the low density and excel ...

Aluminum coil suppliers If you are an aluminum foil buyer, if you want to purchase aluminum foil, you may wish to learn about Huawei Aluminum Foil Factory. We are an aluminum alloy raw material supplier in China. We have 21 years of experience in aluminum foil production and export. We have established supply relationships with more than 70 countries in the world. We are one of the most powerful aluminum foil su ...

Why use 3104 aluminum coil for cans? Aluminum coil is widely used for cans because it is lightweight, durable, and can be easily shaped into various sizes and designs. Here are some of the key reasons why aluminum is a popular material for cans: Lightweight: 3104 aluminum coil is a lightweight material, which means that cans made from it are easy to transport and handle. This is particularly important for the ...

1070 aluminum coil alloy introduction 1070 aluminium coil has some features such as high plasticity, anti-corrosion, electrical conductivity and good thermal conductivity, but low strength. And the machinability is not good without heat treatment. It can be used for gas welding. This specific properties of 1070 aluminium alloy can be used to produce some structures such as aluminium gasket and capacitor, electro ...

What is aluminum 5083 alloy coil? 5083 aluminium coil belongs to Al-Mg-Si aluminium alloys. Its main contents are Magnesium and Silicon except Aluminium. Over 4.0% of Magnesium enables 5083 aluminium coil to have excellent resistance to correction, and easily to welded. By adding cooper, 5083 aluminium coil has 28% Electrical conductivity. 5083 aluminium coil also has good forming characteristic for either hot o ...

5000 Series Alloy Aluminum Coil Overview: What is 5 series aluminum coil? The main element is magnesium, the magnesium content is between 3-5%(Al-Mg Alloy). 5000 series alloy aluminum coil represents 5052, 5005, 5083, 5A05 series. 5000 series aluminum coil belongs to the more commonly used alloy aluminum sheet series. It can also be called an aluminum-magnesium alloy. The main characteristics are low densit ...

Aluminum coil is a metal product that is subjected to flying shear after injection molding and angle drawing in a casting and rolling mill. It is widely used in electronic devices, packaging, engineering construction, mechanical equipment and other fields. So what is the production process of this product? Let me share with you below. 1. Smelter processing Aluminum ingots can be divided into three types: remelt ...

5251 alloy aluminum coil is a commonly used high-strength aluminum alloy material with excellent corrosion resistance and weldability, suitable for various applications. The following are the top ten applications of 5251 alloy aluminum coil: Shipbuilding: 5251 alloy aluminum coils are suitable for the manufacture of ship hulls and decks and other components because of their corrosion resistance and resistance ...

Aluminum coil packaging requirements The packaging of aluminum coils should be based on the specifications and dimensions of the product to choose the packaging box and packaging method. For box packaging, the product cannot be squeezed or moved after being packed in the box. The packaging box can be made of wood, multi-layer board, fiberboard, metal and other materials. The packaging box should be clean and tid ...

The 5251 aluminum alloy is a medium-strength alloy that belongs to the wrought aluminum-magnesium family. It offers several characteristics and properties that make it suitable for various applications. Here are some key characteristics of the 5251 aluminum alloy coil: Strength: The 5251 alloy has medium strength, making it suitable for applications that require a balance between strength and weight. It offers ...

What's the Difference Between Hot and Cold Rolled Aluminum Coil The difference between cold rolled aluminum coil and hot rolled aluminum coil is mainly due to the difference in the production process. Cold rolled is processed by casting machine into casting roll and cold rolling mill. Hot rolling is caused by heating of aluminum ingot. Under the smelting and casting into flat ingots, through the milling s ...

Aluminum roof coil offers several advantages when used for roofing applications. Here are some of the key benefits: Lightweight: Aluminum is a lightweight material, making aluminum roof coil easier to handle and install compared to heavier roofing materials. Its lightweight nature also puts less stress on the underlying structure of the building. Corrosion Resistance: Aluminum has inherent c ...