3004 aluminum coil alloy introduction 3004 aluminium coil is a non- heat treatable aluminium alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 aluminum vs 3003 aluminum coil 3004 aluminium coil belongs to AL-Mn alloy series, which has higher s ...

How much is aluminum coil price per kg? How much is a ton of aluminum coil?How much does an aluminum coil cost?This is a concern of many aluminum coil buyers. Huawei Aluminum shares the latest current price of aluminum sheet coils here for reference by purchasing manufacturers. At present, the quotation method of most aluminum alloy coil manufacturers in the market consists of two parts: aluminum ingot price, ...

What is 1100 series aluminum coil? 1100 aluminum coil is the most commercially pure alloy of all the aluminum grades. 1100 aluminum coil is available for various applications including chemical storage and processing equipemtn. Benefits of 1100 aluminum coil include a 99% or greater content of aluminum compared to other grades of aluminum. 1100 is a low strength aluminum alloy with excellent corrosion resistanc ...

Aluminum coil for cladding panel overview What is ACP(Aluminum composite panels)? Aluminum composite panels (ACP) are built by inserting a soft, shock-absorbent core (typically plastic) sandwiched between two layers of aluminum sheet metal. And one of its main uses is aluminum composite panel cladding for buildings. Aluminum cladding panels coil also called a painted aluminum coil. Aluminum composite pan ...

What is 6061 Aluminium alloy coil? 6061 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6061 aluminum coils is the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum coil provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the "O" t ...

Aluminum coil suppliers If you are an aluminum foil buyer, if you want to purchase aluminum foil, you may wish to learn about Huawei Aluminum Foil Factory. We are an aluminum alloy raw material supplier in China. We have 21 years of experience in aluminum foil production and export. We have established supply relationships with more than 70 countries in the world. We are one of the most powerful aluminum foil su ...

The corrosion resistance of 0.5 mm thick aluminum coils depends on the specific alloy used in making the coils. Different aluminum alloys exhibit varying levels of corrosion resistance due to their elemental composition and the presence of protective surface treatments. Generally speaking, aluminum is known for its excellent corrosion resistance, mainly due to the formation of a thin transparent oxide layer on ...

Aluminum gutter coil is a type of material used for creating seamless gutters. It is typically made from high-quality, durable aluminum alloy, which is known for its resistance to rust and corrosion. Some of the common uses of aluminum gutter coil include: Creating seamless gutters: Aluminum gutter coil is used to create seamless gutters, which offer a more attractive and functional option for managing rainwat ...

Aluminum alloy 3105-H18 is a commonly used material in a variety of industries, especially in sheet, coil and other forms of manufacturing. 3105 H18 aluminum coi has been strain hardened and partially annealed, which has greatly improved its mechanical properties. Corrosion Resistance: Aluminum coil 3105-H18 has excellent corrosion resistance and is suitable for outdoor environments or applications exposed to ...

The thickness of the thinnest aluminum coil can vary depending on the specific manufacturing process, grade of aluminum, and the requirements of the application. Generally, aluminum coils can be produced in a wide range of thicknesses to suit various needs. For standard industrial aluminum coils, the thinnest available thickness is typically around 0.2 mm (200 microns) or even thinner. However, specialized pro ...

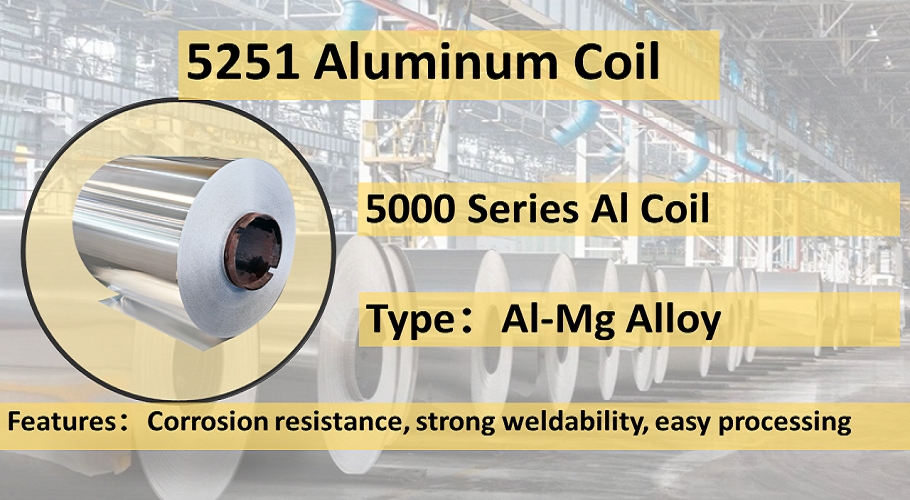

The 5251 aluminum alloy is a medium-strength alloy that belongs to the wrought aluminum-magnesium family. It offers several characteristics and properties that make it suitable for various applications. Here are some key characteristics of the 5251 aluminum alloy coil: Strength: The 5251 alloy has medium strength, making it suitable for applications that require a balance between strength and weight. It offers ...

Aluminum coils are cleaned, chemically converted, and painted to form coatings of various colors and properties on the coils. The aluminum coil is coated by advanced roller coating process, and baked by infrared or hot air circulating baking process. According to the major process points, the process flow is: uncoiling - pre-treatment - roller coating - post-treatment - winding. open book (1) Unwind. The uncoil ...