Huawei 3104 aluminum coil introduction 3104 aluminum coil belongs to modification aluminum alloy, the temper including H111 / 0 / H14 / H16 / H18 / H34, etc. The maximum tensile strength can be controlled equal or at greater than 275MPA, elongation up to 20%. 3104 aluminum coil has good deep-drawing property, which is suitable for thinning the tensile lightweight materials to reduce the quantity of material. The ...

What is 5182 aluminum coil? 5182 aluminum coil is an Al-Mg alloy, which is one of the representative models of 5 series aluminum alloy coils. 5182 aluminum alloy has medium metal strength, good welding performance, and can be anodized on the surface. Its excellent corrosion resistance and plasticity make 5182 aluminum coil widely used in automobile manufacturing and ship transportation. 5182 alloy aluminum ...

Pre painted aluminum coil What is painted aluminum coil?Pre-painted aluminum coil is also called color-coated aluminum coil, which is painted and colored on the surface of the aluminum coil. After painting, it has good corrosion resistance and oxidation resistance, and has a better ornamental effect. Therefore, it is widely used in industrial plants, louver rolls, composite panels, ceilings, tanks and other mate ...

Learn more 3003 h14 aluminum coil 3003 H14 aluminum coil is one of the most common tempers in 3 series aluminum alloy products, and it is also used to make 3003 h14 aluminum circle. The aluminum plate is soft, but slightly harder than the fully soft aluminum plate. It is suitable for shallow stretch products and products that have certain requirements for strength. 3003 h14 aluminum coil has good corrosion resis ...

What is 1100 series aluminum coil? 1100 aluminum coil is the most commercially pure alloy of all the aluminum grades. 1100 aluminum coil is available for various applications including chemical storage and processing equipemtn. Benefits of 1100 aluminum coil include a 99% or greater content of aluminum compared to other grades of aluminum. 1100 is a low strength aluminum alloy with excellent corrosion resistanc ...

Aluminum Coil For Gutter Overview Aluminum gutter coil using aluminum alloy as materials, mainly used in the roof of the building. on the one, on the multilateral side or the whole side made a certain width of depression, the rainwater on the roof along the slope down to the aluminum coil gutter, then discharge through the drain pipe. What is Gutter Coil Used For? For PPGI, general-purpose, color coating, ...

The 5000 series alloys are aluminum-magnesium alloys consisting mainly of aluminum and magnesium. Aluminum coils of this alloy have good corrosion resistance, strength and weldability, and are widely used in industries such as marine, automotive, construction, electronics and packaging. Among the 5000 series alloys, 5052, 5083, 5086 and 5754 are common. Of these alloys, 5052 alloy is the most commonly used bec ...

Product name: aluminum coil 1050 cold rolled SIZE (MM) ALLOY / TEMPER 0.8x340 1050 H14 1.3x150 1050 H14

The density of aluminum alloys may vary depending on the specific alloy composition and the heat treatment process it undergoes. The 4000 series aluminum alloy is a typical aluminum-silicon alloy. The characteristics of the 4000 series aluminum alloy include good corrosion resistance and good welding performance. Common 4000 series aluminum alloys mainly include 4043 4047 4145 aluminum coil 4043 alloy: Cont ...

The thickness of the thinnest aluminum coil can vary depending on the specific manufacturing process, grade of aluminum, and the requirements of the application. Generally, aluminum coils can be produced in a wide range of thicknesses to suit various needs. For standard industrial aluminum coils, the thinnest available thickness is typically around 0.2 mm (200 microns) or even thinner. However, specialized pro ...

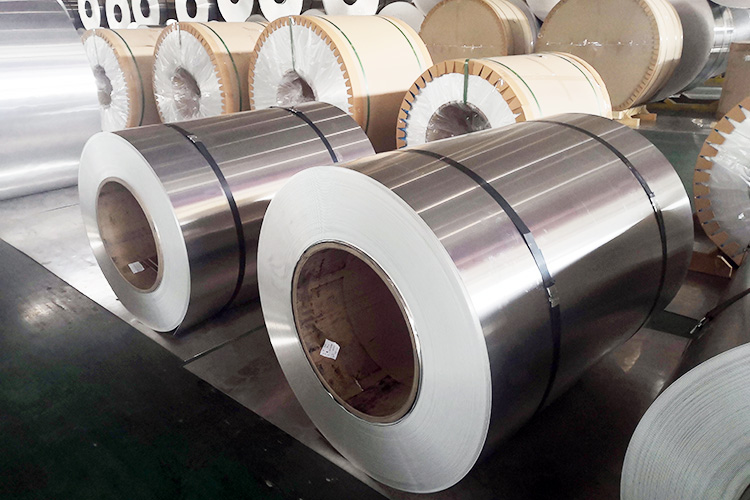

At present, there are many domestic aluminum coil manufacturers, and the consumption of aluminum coils in my country has gradually increased, which is already a very important part of the aluminum industry. Aluminum coil has the characteristics of low density, long service life and beautiful appearance. It is an indispensable product for pipe insulation in power plants and chemical plants. In order to make better ...

Six unique processes for surface treatment of aluminum coils. As aluminum coils become more and more widely used in our lives, everyone has higher and higher quality requirements for aluminum coils. What kind of aluminum coil can attract more users? It is necessary to work hard from the visual effects and surface treatment of aluminum coils. The following is a detailed interpretation of the six unique processes o ...