8000 Series Aluminum Coil Introduce 8 series aluminum coil is one of many aluminum coil models. The mixed metals are mainly Li and Sn. With the addition of other metals, it can significantly reduce the density of a sufficient number of aluminum alloys (usually about approx. 10%, less than other aluminum alloys) can effectively increase the stiffness of the aluminum coil and improve the metal properties of the 8x ...

Aluminum coil custom description: This alloy is an aluminum-based alloy in the "commercially pure" wrought family. With a minimum of 99.0% aluminum. It is the mechanically strongest alloy in the series, and is the only 1000-series alloy commonly used in rivets. At the same time, it keeps the benefits of being relatively lightly alloyed (compared to other series), such as high electrical conductivity, corrosion ...

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum convallis, magna tempus tempor gravida, ante nibh accumsan leo, ut facilisis metus felis ac nunc. Proin purus dui, porta eu metus at, malesuada mollis augue. Sed eu vehicula lectus. Integer placerat, est id cursus ullamcorper, ex nulla lobortis neque, sed bibendum tellus metus eu nunc. Suspendisse potenti. In suscipit, tortor id interdum convalli ...

Aluminum sheet roll for aluminum trim coil overview The aluminum trim coil is widely used for wrapping home’s exterior trim surfaces such as window and door casings, porch posts, drip edge, and fascia. Huawei Aluminum trim coil creates a clean, sharp finish that holds up to harsh weather. It can be field formed into virtually any shape. 1100 aluminum trim coil 1000 series aluminum coil is widely used in ...

Aluminum coil size customization instructions Alloy Thickness(mm) Width(mm) Temper DC or CC 1050,1060,1070,1100,1235,1145 0.2-4.0 20-1500 O,H12,H22,H14,H24,H16,H26,H18 DC, CC 4.0-12.0 1000-1900 H111,H112 DC 3003,3004,3105 0.2-4.0 20-1500 O,H12,H22,H14,H24,H16,H26,H18 DC, CC 4.0-12.0 1000-1900 H111,H112 DC 5052,5083,5754,5005 0.2-4.0 20-1500 O,H12,H22,H14,H24, ...

What is coil Coated aluminum coil? What's color coated aluminum coil? How much do you know about coated aluminum coils? Coated aluminum coils are mainly a product that performs color spraying on the surface of aluminum coils. They are usually called color coated aluminum coils and color aluminum coils. After this treatment, it not only has beautiful effects in the fields of construction, decoration, and home, bu ...

3000 Series Alloy Aluminum Coil Overview: 3000 series alloy aluminum coil represents 3003, 3105 mainly. It can also be called a rust-proof aluminum coil. 3000 series aluminum coil is made of manganese elements as the main component. The content is between 1.0 and 1.5. It is a series with a better rust-proof function. Routinely used in air conditioners, refrigerators, underneath cars, and other wet environments, ...

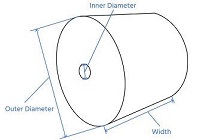

To calculate the weight of an aluminum coil, you need to know the following parameters: Diameter of the Coil (D): This is the outer diameter of the coil, including the aluminum material and any packaging. Inner Diameter of the Coil (d): This is the diameter of the central hole or core of the coil. Width of the Aluminum Strip (W): This is the width of the aluminum material wound into the coil. Thicknes ...

Both 3104 and 3004 are commonly used aluminum alloy coils in various applications, but there are some differences in their chemical composition and properties. The following is a comparison of 3104 aluminum coils and 3004 aluminum coils: chemical composition: 3104 aluminum coil: Aluminum (Al): 95.7% Magnesium (Mg): 0.8-1.3% Manganese (Mn): 0.8-1.3% Zinc (Zn): 0.25% Other elements: Trace other elements 300 ...

The exquisite surface and excellent quality of thermal insulation aluminum coils have become the first choice of users in many fields. Because of the different uses, they need to pay special attention when applying them. So, what are the precautions for the application of thermal insulation aluminum coil? First, if it is to be put into use, it must be at a normal temperature, and the temperature must not be to ...

GB/T 10456-1989 Anodized aluminum hot stamping foil GB/T 9734-1988 Chemical reagents General method for the determination of aluminum GB/T 9538-1988 General specification for ribbon cable connectors GB/T 9489.4-1988 Complexometric titration of alumina content in corundum powder-fluoride release determination method GB/T 9438-1999 Aluminum alloy castings GB/T 8733-2000 Cast aluminum alloy ingots GB/T 6454-19 ...

Features of inferior aluminum profiles: 1. The chemical composition is unqualified. The cost of aluminum profiles doped with a large amount of miscellaneous aluminum and scrap aluminum in the product is greatly reduced, but it will lead to unqualified building aluminum profiles and seriously endanger the stability of construction projects. 2. Inferior aluminum profiles greatly reduce the sealing time, reduc ...