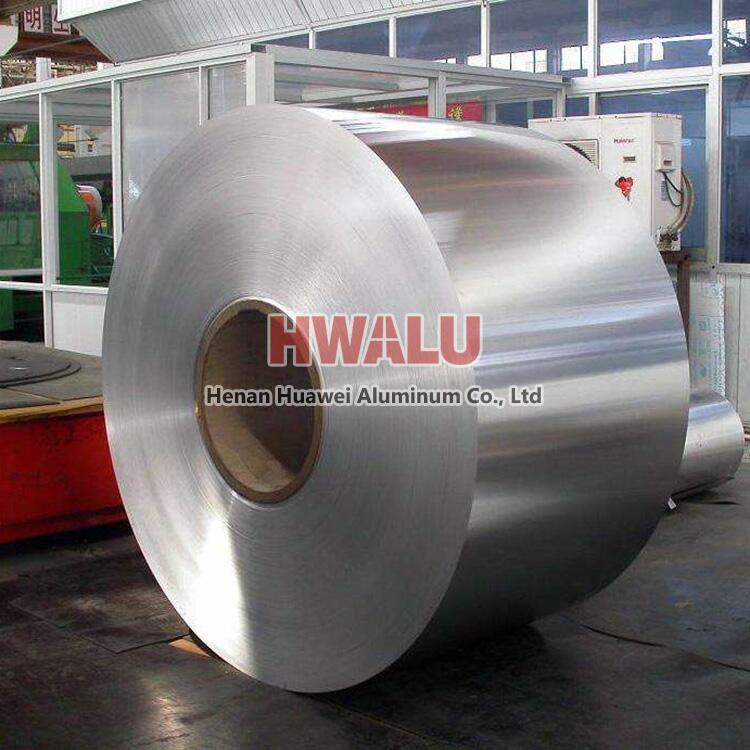

What is 6061 Aluminium alloy coil? 6061 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6061 aluminum coils is the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2xxx and 7xxx alloys, 6061 aluminum coil provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the "O" t ...

Aluminum coil for shutters details: Temper O – H112 Technique Cold Drawn Coil’s standard diameter 1200mm Interior diameter 405mm,505mm, etc. Surface treatment PE or PVDF coating Color solid, metallic, glossy, matte, wooden grain, marble stone,etc. Coating thickness PVDF-25 micron, PE-18 micron Aluminum coil for shutters features: 1.Shutter aluminum coil has wi ...

Learn more 3003 h14 aluminum coil 3003 H14 aluminum coil is one of the most common tempers in 3 series aluminum alloy products, and it is also used to make 3003 h14 aluminum circle. The aluminum plate is soft, but slightly harder than the fully soft aluminum plate. It is suitable for shallow stretch products and products that have certain requirements for strength. 3003 h14 aluminum coil has good corrosion resis ...

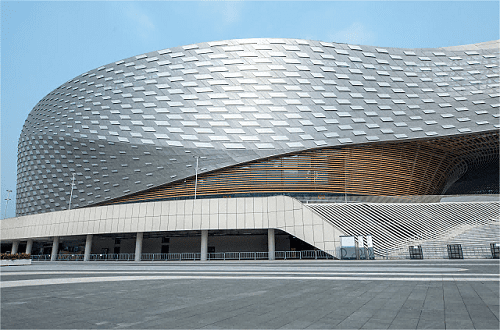

Aluminum coil for cladding panel overview What is ACP(Aluminum composite panels)? Aluminum composite panels (ACP) are built by inserting a soft, shock-absorbent core (typically plastic) sandwiched between two layers of aluminum sheet metal. And one of its main uses is aluminum composite panel cladding for buildings. Aluminum cladding panels coil also called a painted aluminum coil. Aluminum composite pan ...

4000 Series Aluminum Coil Overview: What is 4000 series aluminum coil? 4000 series alloy aluminum coil represents 4A01, 4000 series aluminum coil belongs to the series with the high silicon content. Usually, the silicon content is between 4.5 and 6.0%. It is material for construction, machinery parts, forging, and welding; 4000 series aluminum alloy aluminum coils are aluminum alloys with silicon as the ...

What is 1060 aluminum coil? 1060 aluminium coil is pretty similar to 1050 aluminium alloy with more than 0.1% of aluminium by weight. Both 1050 and 1060 aluminium coil of Huawei AL, lives up to ISO standards, but they cover different ASTM standards. 1060 aluminium coil contains 0.05% cooper, thus, its conductivity is 55%. Besides, the 1060 aluminium coil is relatively low strength, essentially pure aluminium all ...

The 5000 series alloys are aluminum-magnesium alloys consisting mainly of aluminum and magnesium. Aluminum coils of this alloy have good corrosion resistance, strength and weldability, and are widely used in industries such as marine, automotive, construction, electronics and packaging. Among the 5000 series alloys, 5052, 5083, 5086 and 5754 are common. Of these alloys, 5052 alloy is the most commonly used bec ...

Aluminum coils have many uses in the construction field and can be used as building materials. In terms of building structures, aluminum coils can be used to make frames and panels for roofs, exterior walls, doors, windows, balconies, etc. The lightness and high strength of aluminum coils allow it to replace traditional materials such as reinforced concrete and wood, reduce the weight of buildings, and improve th ...

In the process of making aluminum coil, in order to help change its shape, we need to heat it at high temperature. It will be softer at high temperature, and its shape is easier to undergo some changes. Adjust the shape. After that, the temperature can be lowered to maintain a certain hardness. However, in some cases, after the high-temperature cooling is completed, the aluminum coil will have some curling proble ...

Huawei Aluminum sorts out the five characteristics of color-coated aluminum 1. Flatness: no composite high-temperature indentation on the surface, no residual stress on the board surface, and no deformation after shearing; 2. Decoration: painted wood grain, stone grain, with realistic and real texture; 3. Weather resistance: The baked varnish pattern formed by continuous coating and high-temperature baking has ...

At present, there are many domestic aluminum coil manufacturers, and the consumption of aluminum coils in my country has gradually increased, which is already a very important part of the aluminum industry. Aluminum coil has the characteristics of low density, long service life and beautiful appearance. It is an indispensable product for pipe insulation in power plants and chemical plants. In order to make better ...

Both 3104 and 3004 are commonly used aluminum alloy coils in various applications, but there are some differences in their chemical composition and properties. The following is a comparison of 3104 aluminum coils and 3004 aluminum coils: chemical composition: 3104 aluminum coil: Aluminum (Al): 95.7% Magnesium (Mg): 0.8-1.3% Manganese (Mn): 0.8-1.3% Zinc (Zn): 0.25% Other elements: Trace other elements 300 ...