What is 1100 series aluminum coil? 1100 aluminum coil is the most commercially pure alloy of all the aluminum grades. 1100 aluminum coil is available for various applications including chemical storage and processing equipemtn. Benefits of 1100 aluminum coil include a 99% or greater content of aluminum compared to other grades of aluminum. 1100 is a low strength aluminum alloy with excellent corrosion resistanc ...

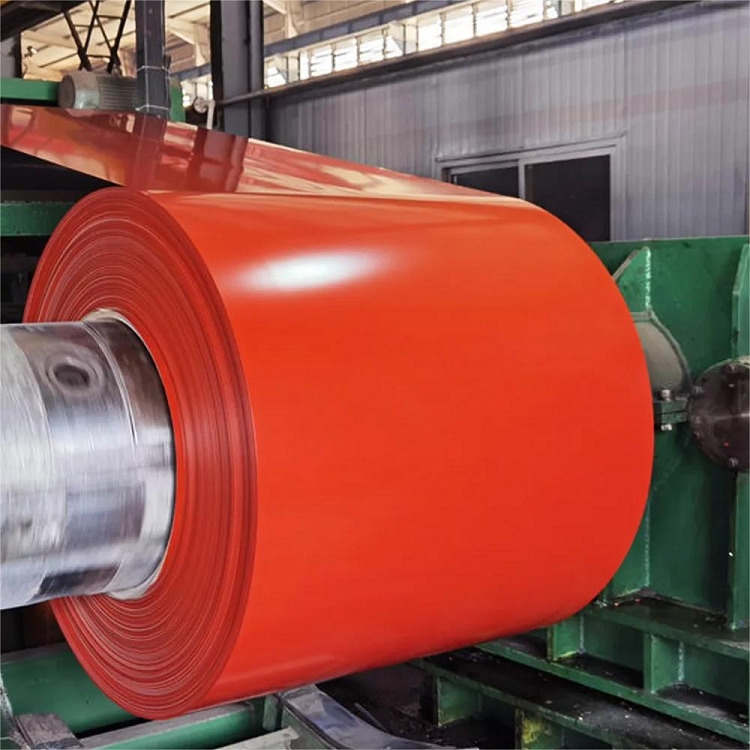

Aluminum coil for cladding panel overview What is ACP(Aluminum composite panels)? Aluminum composite panels (ACP) are built by inserting a soft, shock-absorbent core (typically plastic) sandwiched between two layers of aluminum sheet metal. And one of its main uses is aluminum composite panel cladding for buildings. Aluminum cladding panels coil also called a painted aluminum coil. Aluminum composite pan ...

What is 6063 aluminum alloy coil? 6063 alloy aluminum coil belongs to 6000 series alloy aluminum coil. 6063 aluminum coil is an aluminum alloy with magnesium and silicon as the alloying elements. HuaWei Al delivers customized 6063 aluminum coil, plate and coil with excellent properties like weldability, corrosion resistance and machinability. The mechanical properties of 6063 depend greatly on the temper, or he ...

What is aluminum gutter coil? First we need to know what is a gutter? The gutter refers to the concave part between the two spans of the building roof, which is used to collect rainwater, and the gutter aluminum coil can effectively dredge the roof drainage in an organized manner and play a role in protecting the building. The gutter is divided into inner gutter and outer gutter, and inner gutter refers to the g ...

Aluminum coil suppliers If you are an aluminum foil buyer, if you want to purchase aluminum foil, you may wish to learn about Huawei Aluminum Foil Factory. We are an aluminum alloy raw material supplier in China. We have 21 years of experience in aluminum foil production and export. We have established supply relationships with more than 70 countries in the world. We are one of the most powerful aluminum foil su ...

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum convallis, magna tempus tempor gravida, ante nibh accumsan leo, ut facilisis metus felis ac nunc. Proin purus dui, porta eu metus at, malesuada mollis augue. Sed eu vehicula lectus. Integer placerat, est id cursus ullamcorper, ex nulla lobortis neque, sed bibendum tellus metus eu nunc. Suspendisse potenti. In suscipit, tortor id interdum convalli ...

The 1000 series of aluminum alloys primarily consists of commercially pure aluminum, with minor alloying elements added to improve certain properties. The most common alloy in the 1000 series is 1100, which is often used in various applications due to its excellent corrosion resistance, high thermal and electrical conductivity, and good workability. Some common alloys in the 1000 series of aluminum coils inclu ...

Aluminum Alloy 3003 H18 is a special type of aluminum alloy that is frequently used in a variety of applications. The "H18" designation indicates that the aluminum has undergone a strain hardening process. Here are some common uses of 3003 H18 aluminum coil: Roofing: 3003 H18 aluminum coil is used in the construction industry for roofing and siding materials because of its corrosion resistance and durability. ...

There are a few different methods that can be used to measure the weight of an aluminum coil, depending on the equipment and tools you have available. Here are three common methods: Using a scale: The most straightforward way to measure the weight of an aluminum coil is to use a scale. You will need a scale that can handle the weight of the coil. Place the coil on the scale and ...

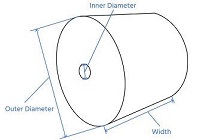

To calculate the weight of an aluminum coil, you need to know the following parameters: Diameter of the Coil (D): This is the outer diameter of the coil, including the aluminum material and any packaging. Inner Diameter of the Coil (d): This is the diameter of the central hole or core of the coil. Width of the Aluminum Strip (W): This is the width of the aluminum material wound into the coil. Thicknes ...

5251 aluminum coil is an alloy of aluminum that belongs to the 5000 series of aluminum alloys. Here are some of the characteristics of this alloy: Corrosion resistance: 5251 aluminum coil has excellent resistance to corrosion, which makes it suitable for use in marine environments and other harsh conditions. High strength: This alloy has a high strength-to-weight ratio, which makes it suitable for use in ...

It is understood that the current aluminum coils on the market are widely used in the production of aluminum composite panels, aluminum ceilings, fireproof veneers, garage doors and other products, but there are certain shortcomings, that is, they don’t pay attention to the protection of aluminum coils after a long time. , There will be corrosion, how to effectively prevent it, let's take a look? (1) Aluminum ...